GOYAL’S

CONCRETE HUB

Kapil Goyal

Proprietor

+91

About us

A Compledte Range Of Products By GOYAL’S CONCRETE HUB

Manufacturing of pavers, spun pipes , concrete blocks and concrete bricks

People tend to throw the terms “paver” “paving stone” “concrete paver” “brick paver” around interchangeably. That is because of the many changes that pavers have undergone over the years, leading to the variety of options on the market today.

Historically, pavers were made from clay or natural stone. As the availability of stone and/or raw materials declined over time, combined with changes in science and manufacturing technology, it was not long before manufactured concrete pavers became the popular hardscape choice.

At Unilock, when we talk about pavers, we are typically referring to the manufactured concrete paving stones that we produce.

Pavers are made on specialized machinery that blends the materials and presses them into paving stones. The ingredients used to create pavers are quite simple:

- Sharp sand

- Small stone chips (about 1/8” or 3 mm in size)

- Cement powder

- Water

- Pigment

- Additives to help with curing, de-molding, and reducing efflorescence.

Although pavers are made on a specialized paver machine/press, the basic ingredients of the concrete are exactly the same as traditional concrete, only with slight changes to the proportions of those ingredients.

Because of the machinery used to mold and press these pavers, these concrete pavers are two to three times stronger than regular poured-in-place concrete. The fact that they are so strong allows us to offer a Lifetime Warranty. The manufacturing process also allows us to create paving stones and retaining wall blocks in a variety of colors, shapes and textures.

Services

Manufacturing

- Pavers

- Spun pipes

- Concrete blocks

- Concrete bricks

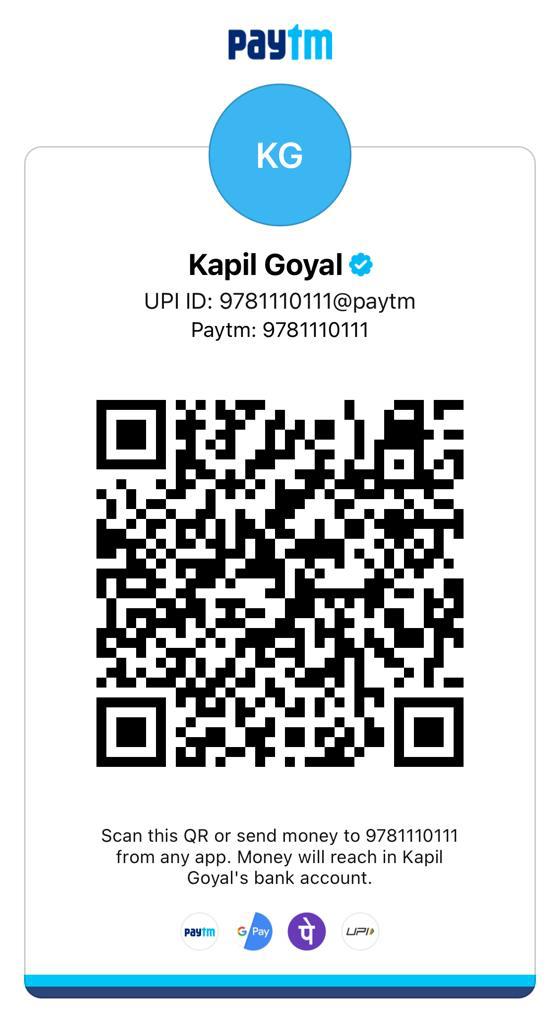

Payment

Pay to Scan